Use on: Medical waste, Industrial Waste, Packaging Material, All kinds of paper cardboard packaging, Tires, and Plastics

- Home |

- Products |

- Waste Shredders |

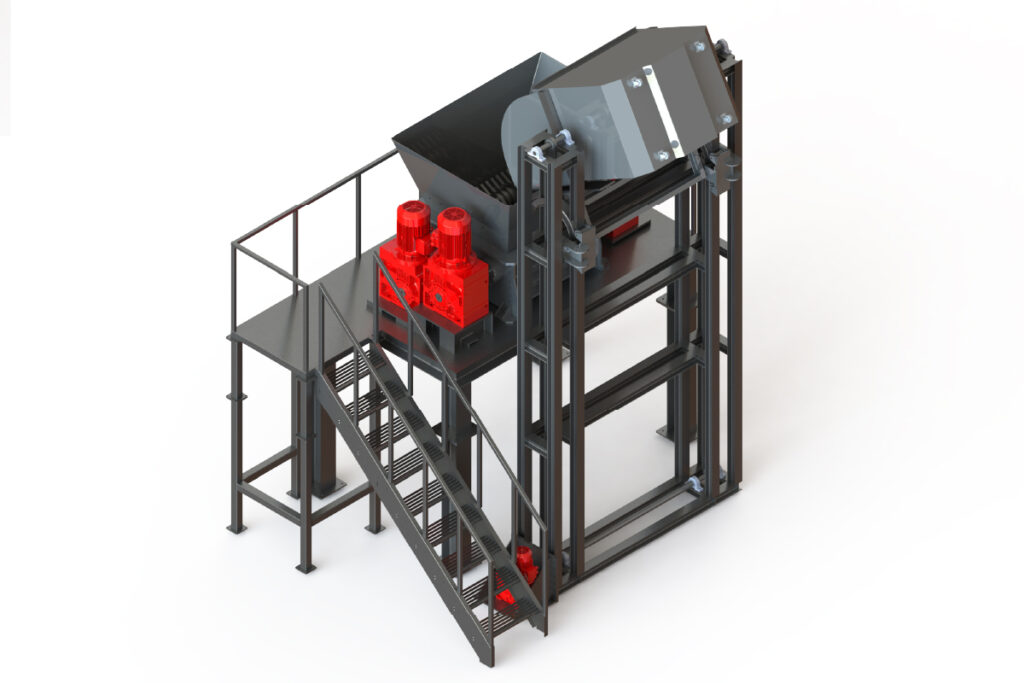

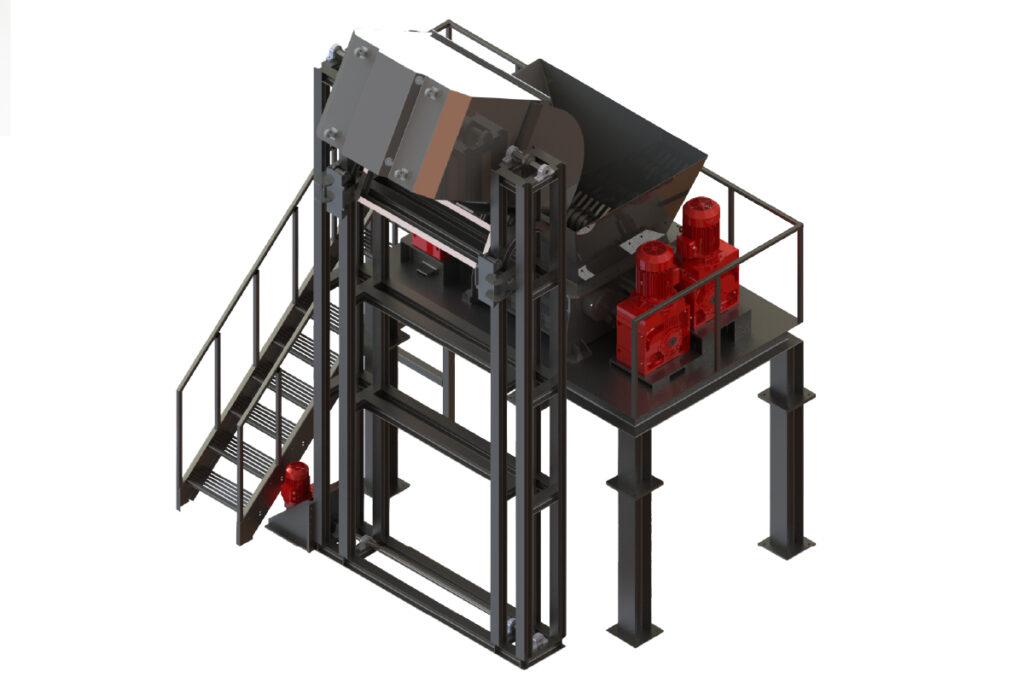

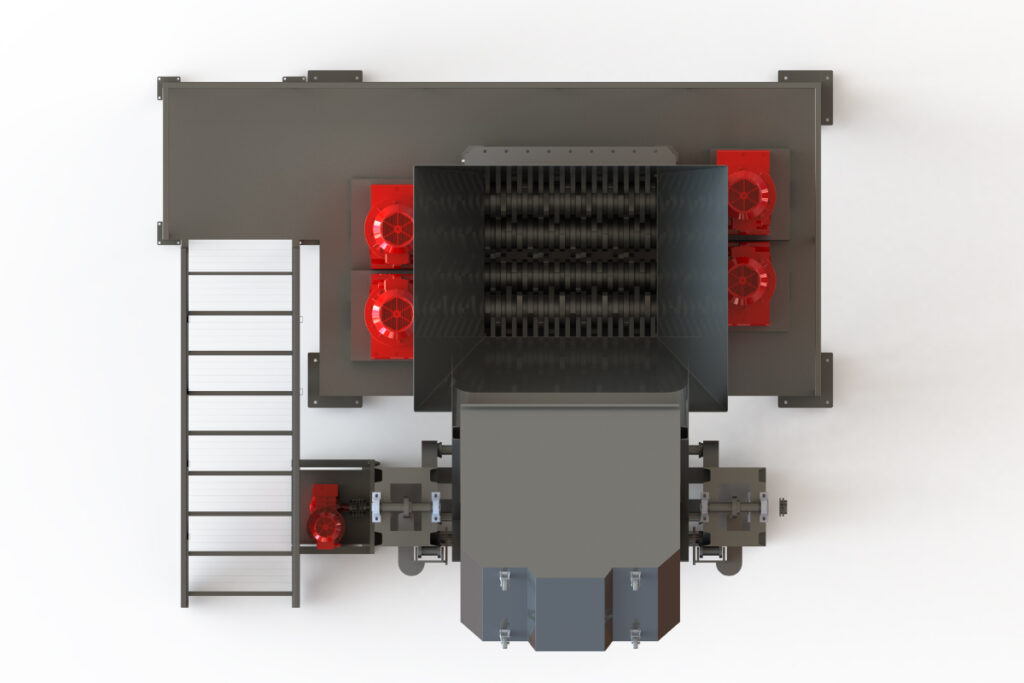

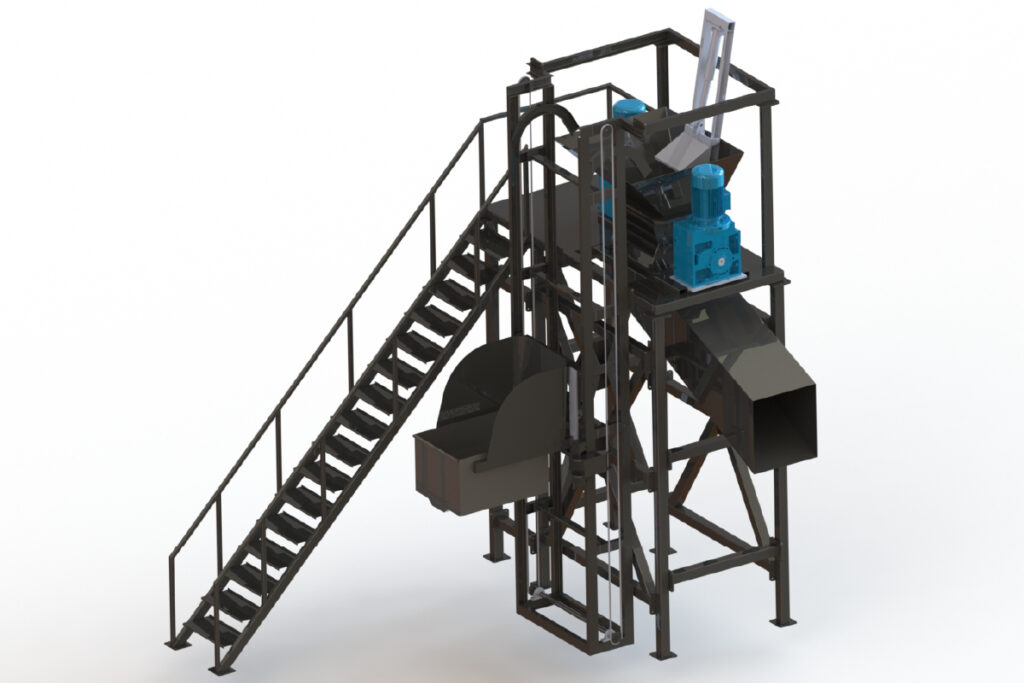

DOUBLE & FOUR SHAFT WASTE SHREDDERS

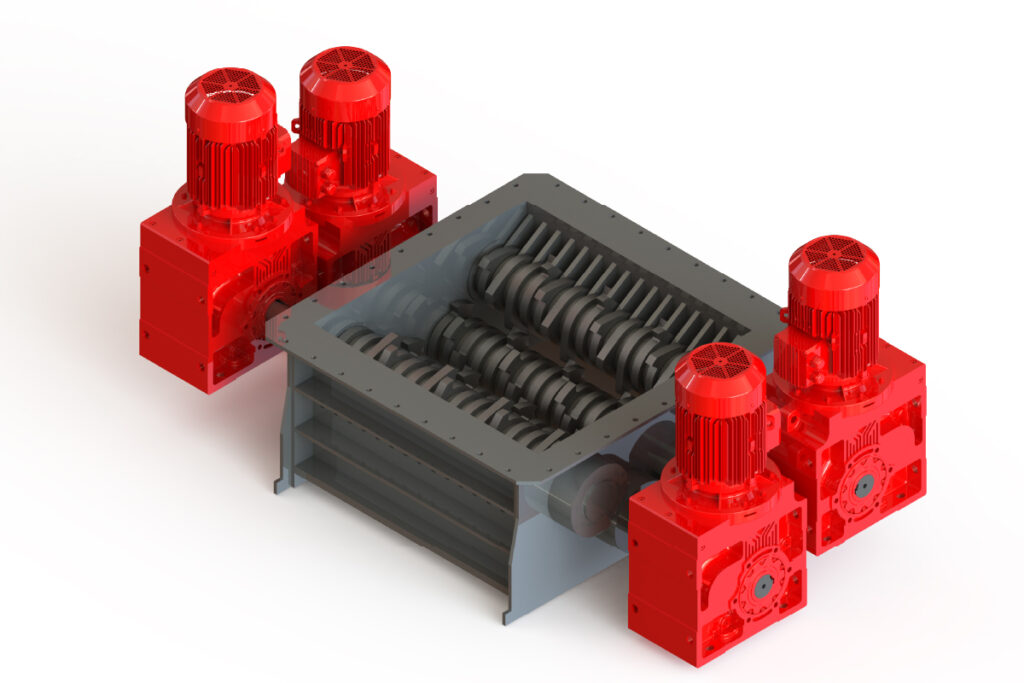

Vertisa dual shaft and four shaft shredders are designed to shred medical waste containing difficult materials such as stainless steel surgical instruments and ceramics.

The shredder, controlled by the PLC, changes its rotation direction due to the “anti-blocking” capability that prevents the blades from getting jammed. VERTISA shredders are driven by an electric powered motor with planetary reducers. The thickness of the cutting disks is between 15,3 mm and 60 mm which can be changed according to the required output sizes and waste types. Throughput sizes can be adjustable by changeable screens.

The research and development department of VERTISA designs shredders for a variety of waste management applications. A special solution is developed “in-house” for shredding paper, cardboard packaging, cardboard tubes, hard drives, electronics, CDs & DVDs, industrial waste, hazardous waste, radioactive materials, organics, tires, steel drums, etc.

PHOTOS

GET FREE QUOTE

Please fill out the form, and one of our sales executives will contact you back.

DESIGN FEATURES

- Automatic elevator option

- Platform with safety bars option

- Motor controlled by driver (Inverter)

- Auto Reverse function prevents clogging

- Manual control of shredder via user interface

- Motor integrated with gearbox (reductor)

- Electrical panel vith color Touchscreen / User interface

- Emergency stop buttons

- High torque, low speed design for efficient shredding

- Cutter disc design for maximum use life

- Bulk feed capacity

- Heavy duty high torque bearing, running in oil bath

- Integrated Conveyor belt for unloading option

- Cleaning fingers keep shredded material from clogging the cutting chamber.

- Special cutter disk design for high efficiency & useful life

- Variable speed optimization for low energy consumption

APPLICATIONS

- Medical waste

- Industrial waste

- Packaging material

- All kinds of paper cardboard packaging

- Tires

- Plastics

- Hard drives electronics CD’s & DVD’s

- Steel drums

SPECIFICATIONS

| TECHNICAL DATA | VD 15 | VD 30 | VD 44 | VD 60 | VD 110 | VQ 30 | VQ 44 | VQ 60 | VQ 88 | VQ 120 | VQ 220 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Shafts | 2 | 4 | ||||||||||

| Driving Power | kW | 1 X 15 | 2 X 15 | 2 X 22 | 2 X 30 | 2 X 55 | 4 X 7.5 | 4 X 11 | 4 X 15 | 4 X 22 | 4 X 30 | 4 X 55 |

| Ram Feeder Power | kW | 5 | ||||||||||

| Number of Cutter Disks | 18 | 30 | 30 | 42 | 52 | 52 | 52 | 52 | 52 | 66 | 66 | |

| Cutter Disk Thichness | mm | 24 | 24 | 24 | 30 | 44 | 24 | 24 | 30 | 30 | 35 | 50 |

| Shaft Diameter | mm | 85 | 85 | 85 | 120 | 160 | 130 | 130 | 130 | 130 | 150 | 190 |

| Cutting Chamber | mm | 505 x 507 | 505 x 607 | 505 x 607 | 875 x 1100 | 875 x 1350 | 840 x 910 | 840 x 910 | 1000 x 1210 | 1000 x 1210 | 1100 x 1300 | 1400 x 1610 |

| Hopper Opening | mm | 1300 x 1300 | 1600 x 1600 | 1800 x 1800 | 2000 x 2000 | 2300 x 2850 | 2000 x 2100 | 2000 x 2100 | 2100 x 2300 | 2100 x 2300 | 2200 x 2500 | 2400 x 2700 |

| Shaft Speed | rpm | 20-35 | 20-35 | 20-35 | 20-35 | 20-35 | 20-35 | 20-35 | 20-35 | 20-35 | 20-35 | 20-35 |

GET FREE QUOTE

Please fill out the form, and one of our sales executives will contact you back.